Consumables

The ZYYX printers have some parts that will not last forever and need to be replaced when they are worn-out or have reached their maximum life span.

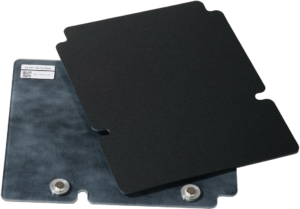

The MagFlex™ Build-Plate Platform System

The ZYYX MagFlex™ Build-Plate Platform System is designed with spring steel build-plates that make removal of prints easy to do by hand. The 3D printer bottom glass platform, adapted with steering pins for easy positioning of the build-plate, is covered with a magnetic layer. Due to the steering pins, the build-plate is swiftly positioned accurately on the glass platform and attaches firmly by magnetic force.

After printing, the build-plate is lifted from the glass base after which the print is removed from the build-plate by bending the plate. The build-plates are available with three different top layers adopted for different print materials.

The ZYYX MagFlax™ system is standard with the ZYYX Pro II and can be purchased as an upgrade for ZYYX Pro and ZYYX+/Classic.

The following ZYYX 3D Print Sheet top layers (TL) are available:

Pro Nylon/PA Top Layer

The removable ZYYX Pro Standard TL is made specially for 3D printing in engineering materials such as proNylon™ and proCarbon™. This surface enables easy 3D printing in our engineering materials without any need for a heated plate or adding temporary materials to the plate surface.

A ZYYX Pro Nylon/PA will last about 6-12 months under normal usage. The top layer even works better when it shows some wear, but should be replaced if the top surface displays larger holes or the glass is cracked.

Multi-Material Top Layer

THe ZYYX Pro Multi-Material TL is created to allow printing in other than our engineering materials. This top layer is not suitable for the engineering materials, but offer optimal printing for our ZYYX PLA™, ZYYX PETG™, ZYYX Flex™, ZYYX PETG-CF™, and many third party filaments.

A ZYYX Pro Multi-Material TL will last about 6 months under normal usage. After this time the surface will have some wear and to ensure good adhesion the TL should be replaced.

Perforated Top Layer

The Perforated TL is optimized for hard-to-print materials that shrink much and tend to warp, such as ABS and ASA. It also works fine for Nylon and TPEE. The adhesion principle is different from a regular build-plate surface in that the raft sticks hard to the perforated holes, anchoring the print firmly to the surface.

The ZYYX Pro Perforated Top Layer is very durable and will keep for many, many prints without wearing out.

ZYYX Pro Standard Build-Plate

Build-Plate for ZYYX Pro with same surface properties as Pro Nylon/PA TL above.

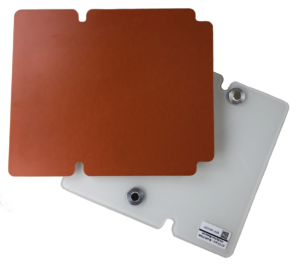

ZYYX Pro Multi-Material Build-Plate

Build-Plate for ZYYX Pro with same surface properties as Multi-Material TL above.

Since 2019, the top surface is thinner and replaceable, and the top surface can be purchased separately.

After 2022 the top surface is thicker and white.

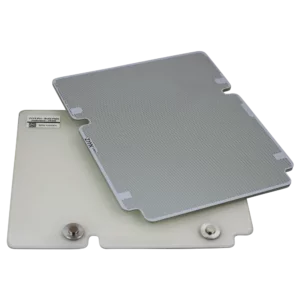

ZYYX Pro Perforated Build-Plate

Build-Plate for ZYYX Pro with same surface properties as Perforeated TL above.

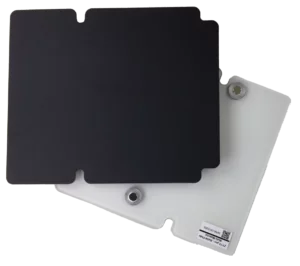

ZYYX/ZYYX+ Build-Plate

The ZYYX+ Build-Plate uses a premium borosilicate glass base plate laminated with a custom plastic surface.

This build-plate surface enables printing with most of the currently available filament types without any need for a heated plate or adding temporary materials to the plate surface.

The build-plate is held in place with three neodymium magnets, making it easy to remove the plate before removing the prints.

A ZYYX+ Build-Plate is supplied with every ZYYX+ 3D printer, and this will last about 6 months under normal usage. After this time the plate surface will have some wear and to ensure good adhesion the plate should be replaced.

Since 2018, the top surface is black instead of white, and the top surface can be purchased separately.

ZYYX/ZYYX+ Perforated Build-Plate

The ZYYX+ or ZYYX Classic Perforated Build-Plate optimized for hard to print materials, like ABS and ASA. The adhesion principle to the Build-plate is different from a regular build-plate in that the raft sticks hard to the perforated holes of the build plate, anchoring the print firmly to the surface.

With this build-plate you can print somewhat larger ABS/ASA models, but due to the heavy shrinkage of ABS, we recommend the ZYYX Pro with its heated build chamber for larger models.

The ZYYX Perforated Build-Plate is very durable and will keep for many, many prints without wearing out.

SwiftTools for ZYYX Pro II

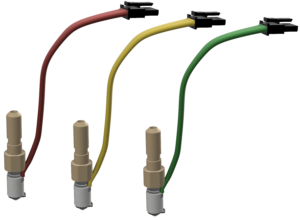

SwiftTool24™ Carbon 0.4, 0.6, 1.2 mm

Nozzle system for ZYYX Pro II that can be used with abrasive materials like proCarbon™, proGlass™, or ZYYX PETG-CF™ like as well as non-abrasive materials like PLA, ASA, ABS, PETG, or proNylon™.

SwiftTool24™ Multi 0.2 mm

Nozzle system for ZYYX Pro II that can be used with non-abrasive materials.

SwiftTools for ZYYX Pro

ZYYX Pro SwiftTool™ Carbon 0.6 mm

An 0.6 mm hardened steel nozzle that can be used with any filament but is optimized for use with abrasive filaments like proCarbon™, proGlass™, or ZYYX PETG-CF™.

ZYYX Pro SwiftTool™ Multi-Material 0.2, 0.4, 0.8 mm

Standard SwiftTools for use with non-abrasive filaments like PLA, ASA, PETG, or proNylon™. Should never be used with proCarbon™, proGlass™, or ZYYX PETG-CF™.

Good to know is that the 0.2 mm SwiftTool is 4-8 times slower than the 0.4 mm when printing the same model. On the other hand, the 0.8 mm is thus 4-8 times quicker than the 0.4 mm and is an excellent choice for quick draft prints.

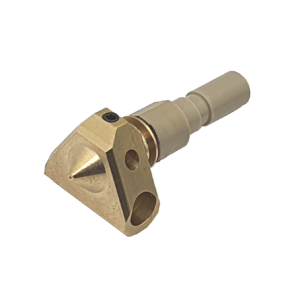

ZYYX/ZYYX+ Hotend

The ZYYX+ hotend is made out of brass, which transfers the heat from the heater to the filament. Set screws to fixate the heater cartridge and temperature sensor are included.

A ZYYX+ Hotend is supplied with the ZYYX+ 3D printer, and will last for a very long time under normal usage and continuous cleaning.

Note! The older ZYYX Classic uses a shorter nozzle. In order for the new nozzle to fit, you may need to drill the aluminum block through and cut away the lower part of the clamping arm. Contact ZYYX for details.

OfficeSafe Ultra™ Filter for ZYYX Pro II

Our new filtering system, a Swedish-made combined HEPA H13 and active carbon filter, removes more than 99.95% of the ultrafine particles, volatile organic compounds, and odors that are created in the air from melting polymers. This innovative, 95 mm thick filter of clean-room class is so efficient that it even cleans the air of the room.

At every-day use of the printer, the filter needs to be replaced every twelve months.

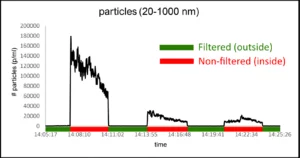

To the right you can see a graph of the particles inside and outside of the printer when printing ABS. This measurement was done with a prototype filter that only absorbs around 99 %.

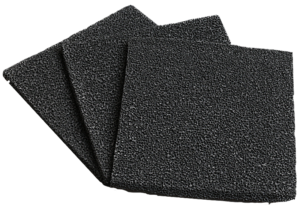

OfficeSafe™ Fume Filter Pack for ZYYX Pro

This filter pack allows for fume-free printing for roughly half a year, as the Fume Filters should be replaced every other month.

It consists of two parts, a black part consisting of activated carbon which absorbs odours and a white part, which is a so-called HEPA filter. The HEPA filter also captures particles.

This filter size is also used by some ZYYX+ printers manufactured 2018 and later.

You can also use these in older printers, but then need an extension frame for the filter holder. Contact ZYYX for details.

ZYYX Fume Filter™ Pack

This filter package will give you a fume-free printing experience for roughly half a year, as the Fume Filter should be replaced every other month.

(Note: Newer ZYYX+ has the same thicker filter as ZYYX Pro, see above)